Need some free safety meeting topics?

How to Conduct an Accident Investigation

In this article we are going to talk about how to conduct a root-cause accident investigation. This is a very important topic because when an injury occurs you want to be able to identify the “root cause” of the accident which led to the injury and implement effective corrective action. Accident investigations are not fault finding. They are fact finding so effective corrective action can be identified and implemented. Many state OSHA programs require employers to have a procedure for investigating accidents and near misses.

Basic Steps for Investigating Accidents

- Decide what questions to ask.

- Conduct employee/witness interviews.

- Identify “root causes” of the accident.

- Identify effective corrective actions to reduce the possibility of a recurrence.

Important Things to Consider During an Accident Investigation

- . Visit the scene of accident before physical evidence is disturbed.

- Make visual records if needed to help understand how the accident occurred (This can be done by using sketches, photographs, notes, condition of area, etc.)

- Determine what accident-related items should be preserved. This could include equipment, tools, PPE, and other items in the area of the accident.

- Identify the people who can help determine accident causes such as eye witnesses or supervisors.

- Interview employees as soon as possible. The more time that passes, the less accurate their memories will be.

- Review any relevant documents, such as work procedures and training records.

- Reenact the events leading up to the accident to get a better understanding about what happened. Obviously, make sure that nobody’s safety is put at risk during a reenactment.

When collecting facts, make sure to:

- Separate facts from opinion or bias.

- Distinguish between direct evidence and circumstantial evidence.

- Prioritize eyewitness testimony over hear-say.

First American Safety offers a variety of safety posers to help companies avoid employee accidents.

-

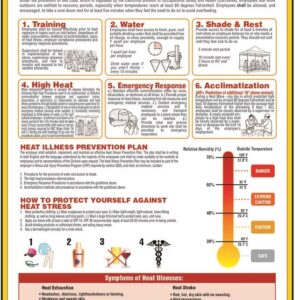

Heat Stress Safety Poster for CaliforniaPrice range: $17.95 through $28.95

Heat Stress Safety Poster for CaliforniaPrice range: $17.95 through $28.95 -

Code of Safe Practices Poster for CAPrice range: $17.95 through $28.95

Code of Safe Practices Poster for CAPrice range: $17.95 through $28.95 -

Forklift Safety Poster for California WorkplacesPrice range: $17.95 through $28.95

Forklift Safety Poster for California WorkplacesPrice range: $17.95 through $28.95 -

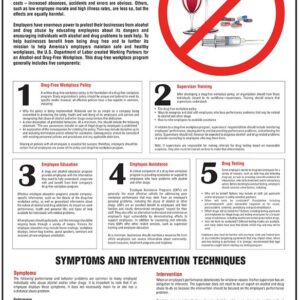

Drug and Alcohol Free Workplace Poster$28.95

Drug and Alcohol Free Workplace Poster$28.95

Questions to Ask During and Accident Investigation

WHO was involved in the accident? Was this a new employee? Were they trained before performing the task which led to the accident, etc.?

WHAT job task was the employee involved doing at the time of the accident? Were the job tasks appropriate for the job being performed at the time of the accident? Should anything have been done differently?

WHEN did the accident occur? What time of day? How long had the employee been working at the time of the accident? Could fatigue play a role in the cause of the accident? Could they have been distracted by thinking about weekend plans or family problems?

WHERE did the accident occur? Was the work area appropriate for the job being performed at the time the accident occurred? Were there too many employees working in the area? Could the equipment being used or not used play a role in the accident or would the equipment in the area have prevented the accident, etc.? Did poor housekeeping play a roll?

WHY did the accident happen? Again, was the employee trained in the job being performed at the time of the accident? Was proper equipment being used or was the employee not using the proper equipment because they did not know how to use it? Should the employee have gotten help with the job they were asked to do? Keep asking why until there are no more why’s to ask.

For example, you can ask, “Why did Joe get hurt?”

Answer: “He was cut while changing a saw blade.”

Question: “Why did the saw blade cut him?”

Answer: “Bob bumped into the power button for the saw while Joe was changing the blade, and it turned on unexpectedly.”

Question: “Why was the saw connected to the energy source while the blade was changed?”

Answer: “Bob thought the job would just take a minute, so he thought he’d save time by not locking out the power.”

Question: “Why did Bob think this was acceptable?”

Answer: “Most people in this company don’t bother with lockout/tagout to do quick jobs. We didn’t think it was a big deal.”

Question: “Why don’t people think it’s a big deal?”

Answer: “The company doesn’t seem to enforce the rule or take it seriously.”

As you can see, asking “why” so many times in this way has led us to a possible root cause- lack of enforcement of safety rules. Management needs to take safety more seriously by enforcing the rules and providing better training. This is the most effective way to determine a root cause during an accident investigation.

HOW could the accident have been prevented? Ask employees including the injured employee (at the appropriate time) what they would recommend to prevent this accident from occurring in the future. Assure employees they can be as candid with you as they need to be without fear of reprisal.

How to Conduct an Interview

- Interview witnesses promptly, separately, and privately. Put the employee(s) at ease, show concern during the interview process.

- Explain the purpose of the investigation.

- Ask the witness to give their version of what happened.

- Avoid any suggestion of blame, name calling, etc.

- Try not to put ideas in their mind.

- Ask questions to clarify your understanding.

- Avoid questions that give a yes or no answer.

- Document any concerns identified in the interview.

- Once again, ask the employee how they would prevent the accident from occurring in the future.

- Take copious notes regarding the accident. Keep the record of the accident on file.

When your accident investigation is complete, a report should be written up and kept on-file. Corrective actions should be planned and implemented. The goal is to eliminate the unsafe actions or conditions that led to the accident so that it never happens again. Near misses should be treated just as seriously.